FRP Grating in Industry - Top 10 Discover Benefits

FRP Grating, also known as Fiber Reinforced Plastic grating, has emerged as a revolutionary material in various industrial applications. Its combination of strength, durability, and resistance to harsh environmental conditions makes it an ideal choice for many sectors seeking reliable and cost-effective solutions. As industries continuously evolve, understanding the advantages of FRP Grating becomes vital for making informed decisions about infrastructure and safety improvements.

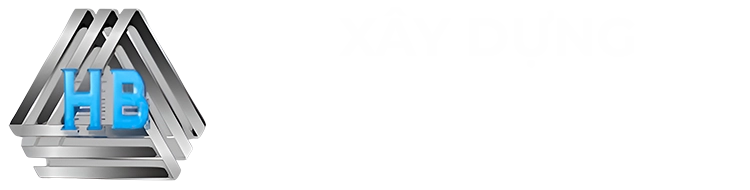

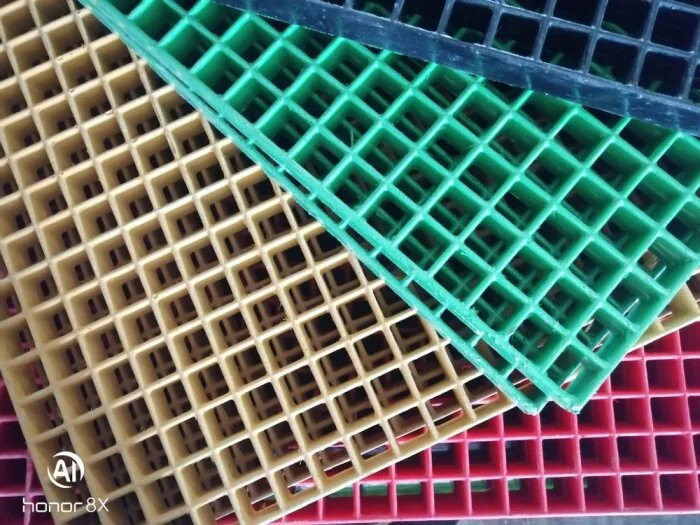

FRP Grating is a composite material comprised of a thermosetting plastic matrix reinforced with fibers, usually fiberglass. This unique construction delivers a lightweight yet sturdy alternative to traditional materials such as steel or wood. Industries ranging from chemical processing plants to offshore oil platforms benefit immensely from its properties. Its ability to withstand corrosive environments, combined with ease of installation and maintenance, positions FRP Grating as a strategic solution for diverse industrial needs.

Before exploring specific benefits, it’s essential to understand why industries are increasingly adopting FRP Grating over conventional materials. The key driver is its excellent resistance to corrosion, which extends the lifespan of infrastructure components and minimizes downtime. Moreover, its high strength-to-weight ratio allows for easier handling and quicker installation processes, saving both labor costs and project timeframes. The versatility of design options further enhances its appeal, enabling customization according to specific load requirements and environmental conditions.

In summary, FRP Grating has become indispensable in modern industry due to its exceptional performance characteristics. It supports safer work environments, reduces maintenance expenses, and contributes to sustainable operational practices. These qualities make it a smart investment for companies aiming to improve safety standards while optimizing operational efficiency.

Mechanical Properties and Load-Bearing Capabilities of FRP Grating

Understanding the mechanical properties of FRP Grating is crucial for assessing its suitability across different applications. Its impressive load-bearing capacity combined with lightweight features provides a balance that traditional materials often struggle to achieve.

Strength and Durability of FRP Grating

The core strength of FRP Grating lies in its fiber-reinforced composition. Fiberglass fibers embedded within a resin matrix grant it remarkable tensile and compressive strength. Unlike metals susceptible to rust and fatigue, FRP Grating maintains its structural integrity over extended periods, even under continuous stress.

From a personal perspective, the durability aspect of FRP Grating truly stands out. In environments where corrosion can cause catastrophic failures—such as chemical plants or outdoor walkways—the resilience of FRP ensures safety and longevity. Its resistance to cracking and warping under fluctuating loads means fewer replacements and reduced long-term costs. Additionally, its ability to withstand impacts without significant damage further underscores its robustness.

When considering use cases, understanding the load capacity of FRP Grating is vital. Engineers typically specify maximum uniform loads to ensure safety margins are maintained. The typical span length of FRP Grating varies depending on thickness, fiber content, and design but generally ranges between several feet to accommodate walking surfaces, platforms, or mezzanines.

What sets FRP Grating apart is its high strength-to-weight ratio. For instance, a steel grating may be significantly heavier, complicating transportation and installation, whereas FRP reduces these logistical challenges. Moreover, its modular nature allows for customizable spans and load capacities, making it adaptable to complex structural requirements.

From a practical standpoint, industries appreciate that FRP Grating combines strong load support with ease of handling. Whether installed in expansive outdoor facilities or confined indoor environments, this material adapts seamlessly without compromising safety. Its mechanical properties also mean that the product remains reliable over years, offering peace of mind where failure could have severe consequence.

Industrial environments are often subjected to repetitive loading, vibrations, and impact forces. Therefore, resistance to mechanical wear and fatigue is essential for any flooring or structural element.

FRP Grating excels here because the fiber reinforcement distributes stresses evenly throughout the structure, reducing localized weaknesses. Over time, this translates into minimal degradation, even under frequent traffic or heavy machinery movement. Its surface can be treated or textured to enhance slip resistance, further improving safety during wet or oily conditions.

In my analysis, the fact that FRP Grating retains its mechanical properties over decades without significant deterioration is transformative. It minimizes maintenance needs and prevents costly downtime caused by structural failures. This reliability underscores its importance in critical industries where safety and operational continuity are paramount.

Corrosion and environmental degradation are pervasive concerns in many industries, especially those involving exposure to chemicals, moisture, or extreme weather. Materials prone to rust or decay require ongoing maintenance, which can be disruptive and expensive.

One of the most notable features of FRP Grating is its superior resistance to a wide range of corrosive substances. Unlike metals that readily oxidize or degrade when exposed to acids, alkalis, or solvents, FRP's polymer matrix acts as a protective barrier. This characteristic makes it particularly suitable for chemical processing facilities, wastewater treatment plants, and marine environments.

In practical situations, using FRP Grating significantly reduces the need for coatings or protective layers. This not only cuts down on maintenance costs but also eliminates the risk of chemical leaks or failures due to coating deterioration. Furthermore, the ability to select specific resin formulations tailored to particular chemical exposures enhances its versatility.

Environmental durability extends beyond chemical resistance. Exposure to moisture and UV radiation can cause traditional materials like wood or unprotected metals to deteriorate. FRP Grating, however, exhibits excellent resistance to moisture absorption, preventing swelling, warping, or fungal growth.

UV stability can be achieved through special additives in the resin, allowing the material to withstand prolonged sunlight exposure without embrittlement or discoloration. High temperatures and thermal cycling also pose challenges, yet FRP Grating maintains its structural integrity under fluctuating thermal conditions, making it suitable for outdoor walkways or platforms exposed to sun and rain.

From a personal insight, the environmental resilience of FRP Grating aligns well with sustainable building practices. Its long service life and low maintenance needs contribute to reduced material consumption and waste, supporting eco-friendly industry standards.

While FRP Grating offers outstanding resistance, understanding how environmental factors influence its longevity is essential. Proper selection of resin systems and manufacturing techniques can enhance performance. Regular inspections, combined with appropriate protective coatings if necessary, further extend the lifespan.

In analyzing real-world applications, I observe that facilities embracing FRP Grating report significantly less downtime related to corrosion-related repairs. The upfront cost may be higher than traditional options, but the lifecycle benefits far outweigh initial investments. Ultimately, the resilience against environmental factors solidifies FRP Grating’s reputation as a durable, cost-effective choice for demanding industrial settings.

Financial considerations play a pivotal role in adopting new materials. Although the initial expenditure for FRP Grating might be higher compared to traditional options like steel or wood, its long-term savings and environmental benefits often justify the investment.

FRP Grating’s resistance to corrosion, impact, and wear reduces the frequency of repairs and replacements. Its durable nature means fewer shutdowns and lower maintenance labor costs over its service life. Additionally, the ease of installation minimizes labor hours, contributing further to cost savings.

In my experience, organizations that switch to FRP Grating often see a rapid return on investment. The material's longevity translates into fewer disruptions, reduced inventory for spare parts, and enhanced safety protocols—ultimately leading to substantial operational savings.

From an ecological perspective, FRP Grating supports sustainable practices. Its long lifespan reduces the need for frequent replacements, decreasing resource consumption and waste generation. Moreover, advancements in resin technology now enable the use of environmentally friendly, recyclable materials.

Furthermore, because FRP Grating does not require painting or coatings that contain volatile organic compounds (VOCs), its use results in lower emissions and a healthier environment for workers and nearby communities. The ability to manufacture customized designs that optimize material usage also minimizes waste.

In the broader context, industries adopting FRP Grating demonstrate a commitment to sustainability, aligning with global efforts to reduce carbon footprints and promote green infrastructure.

| Material | Initial Cost | Maintenance Cost | Lifespan | Corrosion Resistance | Overall Durability |

|---|---|---|---|---|---|

| Steel | Moderate | High | 10-20 years | Poor | Moderate |

| Aluminum | Slightly high | Moderate | 15-25 years | Fair | Good |

| Wooden | Low | Very high | 7-12 years | Poor | Low |

| FRP Grating | Slightly high | Very low | 30+ years | Excellent | Superior |

This table encapsulates the comparative advantages of FRP Grating, emphasizing its balance of cost-efficiency, durability, and environmental resilience.

The versatility of FRP Grating lends itself to numerous applications across various industries. Each sector benefits uniquely from its properties, resulting in safer, more sustainable, and cost-effective operations.

In environments where chemical exposure is unavoidable, FRP Grating's resistance to acids, alkalis, and solvents makes it indispensable. Platforms, walkways, and storage areas built with FRP offer long-lasting structural performance, reducing maintenance intervals and preventing accidental spills or leaks caused by corrosion-related failures.

Corrosion is a constant challenge in marine environments. Traditional materials deteriorate rapidly under saltwater exposure, necessitating frequent replacements. FRP Grating’s inherent resistance to salt, moisture, and UV radiation ensures structural integrity, facilitating safer operations and lowering lifecycle costs.

Cleanliness and hygiene are critical in food and pharmaceutical manufacturing. FRP Grating’s non-porous surface, coupled with its resistance to mold and bacteria, makes cleaning straightforward and effective. Its compliance with sanitary standards helps companies maintain product integrity and adhere to regulations.

Bridges, pedestrian walkways, and stadiums benefit greatly from FRP Grating’s lightweight and high-strength properties. Easy installation and reduced load requirements support large-scale infrastructure projects, ensuring safety and longevity while minimizing environmental impact.

Heavy machinery and rugged terrain demand resilient flooring that can withstand impacts and heavy loads. FRP Grating offers a durable, slip-resistant surface that improves worker safety and operational efficiency in such demanding settings.

Dự án đã thực hiện khác

- So sánh sàn grating FRP composite ô 19x19 với các loại sàn khác

- Tìm hiểu lợi ích của sàn grating FRP ô 19x19

- Sàn Grating FRP Ô 19x19 Giải pháp vật liệu composite tối ưu cho công nghiệp và dân dụng

- Komposittgitter – Fremtiden for byggeindustrien

- Трендови во употребата на композитни решетки за подови во модерната градба

- Komposiittimateriaalien käyttö rannikkoalueiden rakennushankkeissa

- Miért fektetnek egyre több vállalkozás a kompozit anyagokba?