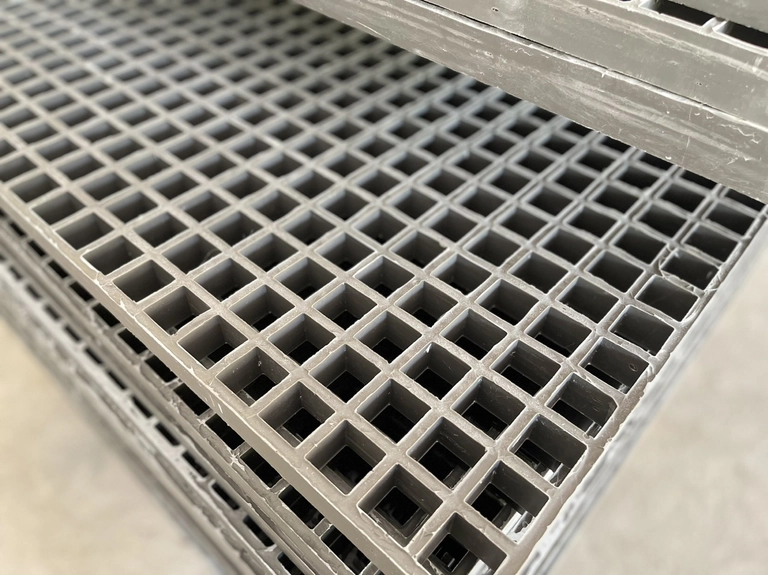

Composite Grating for Factory Managers

Today, composite grating floors are becoming the top choice for factory managers, thanks to their outstanding advantages in durability, corrosion resistance, and flexibility in applications.

In the past, traditional materials such as steel were often limited by poor corrosion resistance, leading to high maintenance costs.

With the introduction of composite grating floors, factories now have a more efficient solution, helping to extend the lifespan of the facility and reduce operating costs.

In addition, this material helps optimize production processes, offering significant economic and environmental benefits.

1. Outstanding Corrosion Resistance

The corrosion resistance of this material is one of the key factors that make it highly favored by factories.

Corrosion-resistant industrial floors are particularly important for factories operating in highly corrosive environments, such as the chemical, oil, gas, or coastal industries.

Unlike traditional materials like steel, composite grating floors are not affected by harsh environmental conditions.

2. High Durability and Load-Bearing Capacity

In addition, composite grating floors are highly durable and have excellent load-bearing capacity. While they are lighter than steel, these floors can withstand heavy loads without deforming.

This is why they have become the sustainable factory floor solution and high load-bearing composite floors are an ideal choice for environments requiring high load-bearing capacity.

This not only ensures safety during use but also extends the product lifespan, reducing maintenance and replacement costs.

3. Electrical Safety Features and UV Resistance

Another advantage of composite grating floors is their low electrical conductivity and UV resistance.

For areas with high electrical safety requirements or exposure to sunlight, this is an ideal choice.

UV-resistant grating floors also have excellent thermal insulation properties, reducing the risk of fire and explosions in high-temperature factories, ensuring safety for production activities.

4. Economic Benefits of Using Composite Grating Floors

Not only does composite grating floor offer technical advantages, but it also brings numerous economic benefits to businesses.

4.1. Maintenance Cost Savings

Firstly, using composite grating floors helps reduce maintenance and replacement costs.

With a long lifespan and excellent corrosion resistance, factories can save a significant amount on maintenance and repairs, especially for large-scale, continuous operations.

This shows that this cost-effective flooring material is not only suitable for large projects but also for factories that need to operate continuously.

4.2. Reduced Structural Weight

Additionally, composite grating floors help reduce the structural weight of the building.

This leads to reduced load on the foundation and columns of the factory, not only saving construction costs but also enhancing the stability and safety of the entire structure.

4.3. Environmental Benefits of Composite Grating Floors

Environmentally, composite grating floors are highly regarded for their sustainability and recyclability.

Using these corrosion-resistant industrial floors helps reduce industrial waste and decrease reliance on non-renewable resources.

This not only helps businesses fulfill their social responsibility but also creates an environmentally friendly image in the eyes of partners and customers.

As the industrial sector continues to grow, the demand for sustainable and cost-effective material solutions is increasing.

Composite grating floors not only meet the stringent technical requirements but also provide significant economic and environmental benefits.

This makes them a sustainable factory floor solution for factory managers, particularly in industries that require high durability and corrosion resistance.

Investing in composite grating floors is a smart and sustainable decision for businesses, helping them ensure continuous and efficient production operations in the long run.