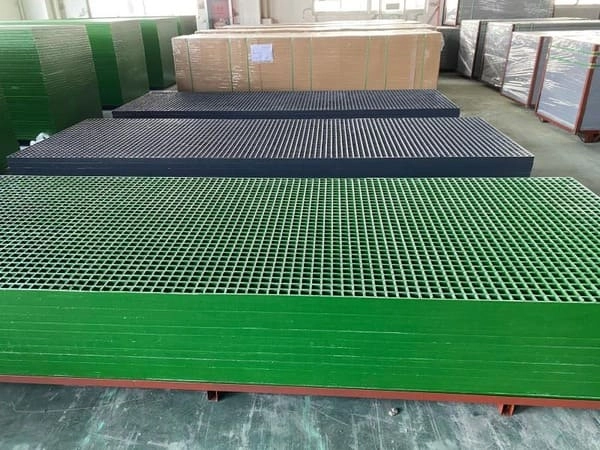

Composite Grating Flooring for Manufacturing Plants

Composite grating floors are becoming a popular and effective solution for many modern manufacturing plants. This product not only meets durability and performance requirements but also offers many superior advantages compared to traditional flooring types.

1. Advantages of Composite Grating Floors

Made from composite materials, typically a combination of composite plastic and other components, one of the major advantages of these floors is their corrosion resistance.

With manufacturing plants often exposed to chemicals and wet conditions, the corrosion-resistant nature of composite grating floors helps minimize damage risks and extends the lifespan of the floor.

In addition, composite grating floors also have high load-bearing capacity. This is crucial in plants with heavy equipment and materials that need to be moved. With its special design, this floor distributes weight evenly and minimizes the risk of breaking or deformation.

2. Technical Characteristics

Composite grating floors are typically made from fiberglass reinforced in epoxy or polyester resin, creating a lightweight yet incredibly sturdy product.

The slip-resistant property of composite floors is another big advantage, enhancing safety for workers when moving in wet or slippery environments.

Additionally, composite grating floors offer better fire resistance compared to other materials. This is especially important in manufacturing plants, where the risk of fire and explosion can be a concern. The fire-resistant standards of composite floors help protect the plant and reduce risks.

3. Applications in Manufacturing Plants

This product is widely used in various types of manufacturing plants, including:

- Chemical plants: Composite floors are highly resistant to chemicals, helping to protect the floor structure and ensure worker safety.

- Food processing plants: With slip resistance and ease of cleaning, composite floors are ideal for environments that require high hygiene standards.

- Power plants: Composite floors have high load-bearing capacity and fire resistance, suitable for the stringent requirements of the power industry.

4. Economic Benefits

Although the initial cost of composite grating floors may be higher than other types of flooring, the long-term economic benefits are undeniable.

The high durability and low maintenance requirements help reduce overall costs. Composite floors are also capable of withstanding harsh conditions, reducing replacement and repair costs.

5. Installation and Maintenance

Installing composite grating floors is quite simple and quick. The grating panels can be cut to the required size and easily installed without the need for special tools. Maintaining composite floors is also very easy. Regular cleaning and periodic checks will help maintain the floor in good condition.

This product offers numerous advantages for manufacturing plants, including high durability, corrosion resistance, and slip resistance, along with excellent technical characteristics.

Using composite grating floors not only improves operational efficiency but also ensures worker safety and saves on long-term maintenance costs. With these advantages, composite grating floors are the smart choice for modern manufacturing plants.