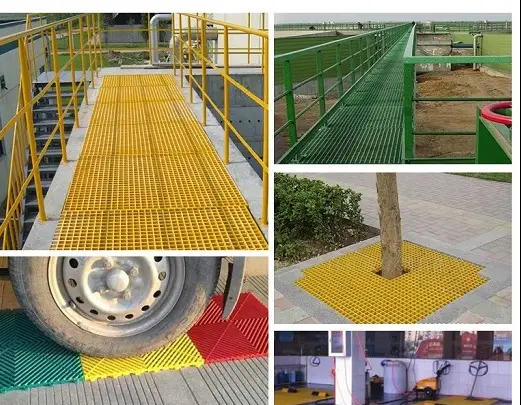

Comparison Between Composite Grating Flooring and Traditional Steel Flooring - Top 5 Advantages and

Comparison of composite grating floors and traditional steel floors.

The composite grating floor and traditional steel floor are two common materials used in construction and industry. Each has its own advantages and disadvantages, depending on the specific needs of each project. In this article, we will analyze and compare these two types of floors to help you make the right decision for your project.

Comparison of composite grating floors and traditional steel floors: Overview

In this section, we will examine an overview of the characteristics and structure of composite grating floors and traditional steel floors. Understanding these two types of floors will help you have a clearer view before making your selection decision.

Definition and Structure

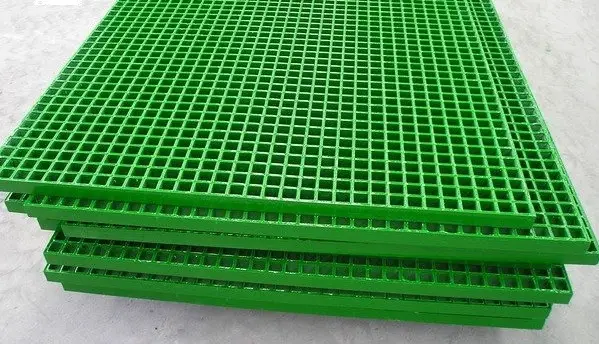

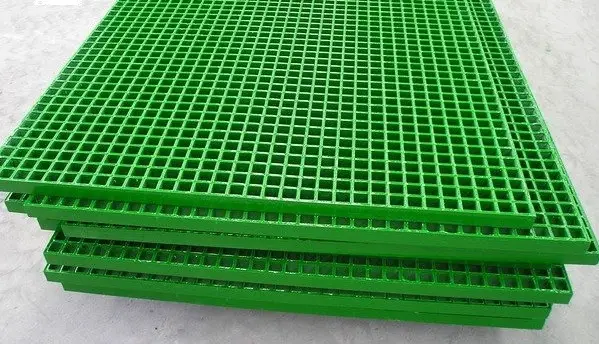

The composite grating floor is made from a mixture of rigid plastic and fiberglass, forming horizontal and vertical bars that create a solid and lightweight structure. Composite grating floors are commonly used in environments that require high corrosion resistance and load-bearing capacity.

In contrast, the traditional steel floor is made entirely of steel, providing high durability but is heavier. Steel floors are typically used in constructions that require large load-bearing capacity and good fire resistance.

Factors Influencing the Choice

When choosing between composite grating floors and traditional steel floors, many factors need to be considered, including:

- Usage environment

- Physical and mechanical properties

- Initial investment and maintenance costs

- Corrosion resistance and chemical resistance

With these factors in mind, comparing and evaluating the two types of floors will help you make the most suitable decision for your needs.

Advantages of composite grating floors over traditional steel floors

Composite grating floors have many significant advantages over traditional steel floors that we cannot overlook. These advantages affect not only performance but also the cost and sustainability of the project.

Lightweight

One of the biggest advantages of composite grating floors is their lightweight. With a fiberglass structure, the FRP composite grating floor is much lighter than steel floors, which provides great benefits during transportation and installation.

The lightweight also reduces the load on the underlying structure, increasing the lifespan of the building and reducing foundation costs.

Corrosion resistance

Composite grating floors have outstanding corrosion resistance due to the nature of the material. In wet environments or when exposed to chemicals, composite grating floors do not rust or deteriorate like steel floors. This makes composite grating an ideal choice for factories, ports, or chemical areas.

Easy maintenance

Maintaining composite grating floors is also much easier. They do not need to be painted or treated frequently like steel floors, saving time and maintenance costs for investors.

Furthermore, the surface of composite grating floors is often designed to be slip-resistant, enhancing safety for users.

Disadvantages of composite grating floors and traditional steel floors

Although composite grating floors have many advantages, they also have certain disadvantages. Similarly, traditional steel floors also have some limitations that need to be considered.

High initial investment cost

One of the major drawbacks of composite grating floors is the high initial investment cost, which is usually higher than traditional steel floors. This can cause hesitation among many investors when making a selection decision.

Lower load-bearing capacity

While composite grating floors are durable, they usually do not bear as much load as steel floors. Therefore, for projects requiring high load capacity, steel floors are still a better choice.

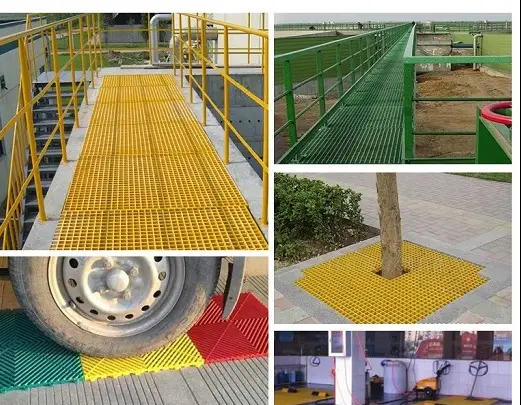

Applications of composite grating floors in industry

Composite grating floors are increasingly popular in many industrial fields due to their superior features and adaptability to various environments.

Oil and gas industry

In the oil and gas industry, where corrosive chemicals are prevalent, composite grating floors are an optimal solution. This product not only ensures safety but also helps reduce maintenance costs due to its corrosion resistance.

Food industry

Composite grating floors are also widely used in the food industry, where high hygiene standards are required. Their waterproof surface and easy-to-clean design ensure food safety standards are met.

Healthcare industry

In the healthcare industry, cleanliness and safety for patients are top priorities. Composite grating floors meet these requirements with their slip-resistant design and ability to resist bacteria.

Safety features of composite grating floors and traditional steel floors

Safety is one of the most important factors in selecting building materials. Both composite grating floors and traditional steel floors have their own safety features.

Slip resistance

The surface of composite grating floors is often designed to be slip-resistant, preventing accidents in wet environments. In contrast, traditional steel floors can be coated with a slip-resistant layer but are not naturally slip-resistant like composite grating floors.

Load-bearing capacity

Traditional steel floors have a higher load-bearing capacity, making them suitable for projects requiring high load resistance. However, composite grating floors have significantly improved with new designs to increase their load-bearing capacity.

Cost and maintenance of composite grating floors and traditional steel floors

Cost and maintenance are important factors when choosing between composite grating floors and traditional steel floors.

Initial investment cost

The initial investment cost for traditional steel floors is usually lower than for composite grating floors. However, it should be noted that maintenance costs for steel floors can increase over time due to rusting.

Maintenance costs

Composite grating floors typically have lower maintenance costs since they do not require frequent maintenance, whereas steel floors may need more frequent replacements or repairs.

| Floor Type | Initial Investment Cost | Maintenance Cost |

|---|---|---|

| Composite grating floor | High | Low |

| Traditional steel floor | Low | High |

Corrosion resistance of composite grating floors and traditional steel floors

Corrosion resistance is one of the decisive factors in choosing a floor, especially in harsh environments.

Composite grating floor

Composite grating floors have absolute corrosion resistance due to the rigid plastic material. They can withstand strong chemicals, seawater, and many other chemicals without being affected.

Traditional steel floor

In contrast, traditional steel floors are prone to corrosion and rust if not properly maintained. This can lead to a decline in the quality of the floor over time, posing a risk to users.

Design of composite grating floors and traditional steel floors: The difference

Design also plays an important role in determining the features and applications of each type of floor.

Style and size

Composite grating floors come in a wider range of styles, sizes, and shapes to fit various applications. Traditional steel floors, on the other hand, usually have a simpler and more fixed design.

Customization

Composite grating floors are easier to customize during production, allowing them to meet the specific needs of each project. Steel floors are typically less flexible in this regard.

Choosing between composite grating floors and traditional steel floors for your project

Choosing between composite grating floors and traditional steel floors depends on many factors, from specific needs to the projected budget.

Assessing needs

To make the right decision, you need to clearly assess the needs of your project. If your project is in an environment with many corrosive chemicals, composite grating floors will be the optimal choice.

Calculating the budget

Additionally, you need to calculate the budget for the project. If the budget allows, investing in composite grating floors could provide longer-term benefits in terms of maintenance and durability.

The future of composite grating floors and traditional steel floors in the construction industry

The future of composite grating floors and traditional steel floors will depend on the development of technology and market demands.

Development trends

Today, the trend of using new, environmentally friendly materials is on the rise. Composite grating floors, with their corrosion resistance and easy maintenance, are becoming more popular in many fields.

Challenges for steel floors

Traditional steel floors are facing many challenges due to maintenance and lifespan issues. Therefore, researching and developing improved solutions for steel floors is necessary to maintain their position in the market.

Conclusion

In choosing between composite grating floors and traditional steel floors, each has its own advantages and disadvantages. Composite grating floors stand out for their corrosion resistance and lightweight, while traditional steel floors have better load-bearing capacity. Depending on the usage environment and project requirements, you can make the most suitable choice for yourself.