10 Differences: Comparing Composite Grating Flooring with Other Types of Flooring

General Introduction to Composite Grating Flooring

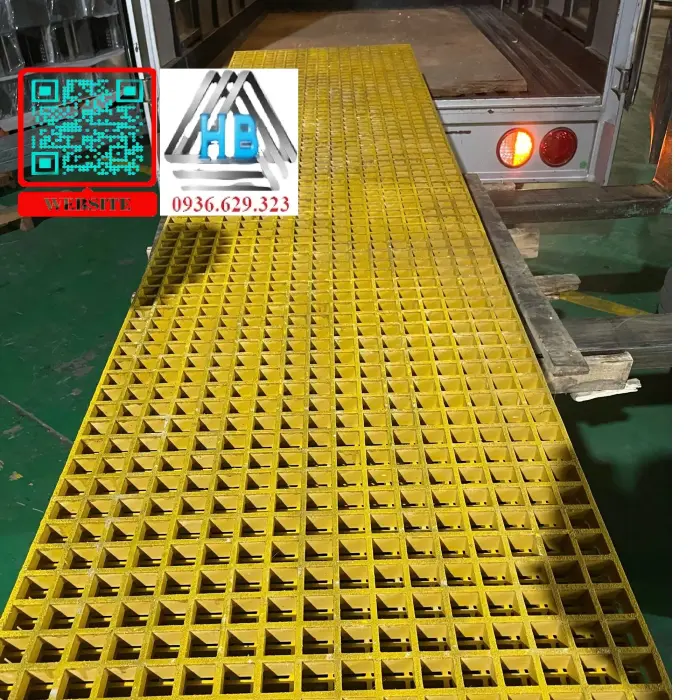

Composite grating flooring is a type of flooring made from materials primarily consisting of aluminum alloy or galvanized steel, combined with composite layers to form a flooring system with excellent load-bearing capacity, high aesthetics, and ease of installation. This type of flooring is commonly used in factories, workshops, docks, or heavy industrial areas that require resistance to corrosion, fire, and quick water drainage.

In this section, we will delve into the structure and key features of composite grating flooring to understand why it is so popular in the market today.

Structure of Composite Grating Flooring

The structure of composite grating flooring is quite unique, combining multiple layers of materials to optimize usage features. The main frame is typically made of aluminum alloy or stainless steel, which provides good corrosion resistance, with a composite material layer on top that offers strength, impact resistance, and superior corrosion resistance.

The surface of the flooring can be designed as a grating (grid) or solid, depending on the intended use. Various cut patterns help increase water drainage capacity, reduce overall weight, and ensure safety for users.

Outstanding Advantages of Composite Grating Flooring

- Corrosion and Rust Resistance: Thanks to the alloy structure and special coating layer, it minimizes the risk of oxidation in humid environments or those with many chemicals.

- Lightweight and Easy to Transport: Compared to traditional concrete or steel flooring, composite grating flooring is much lighter, reducing the load on the structure of the building.

- Good Water Drainage Capacity: The grid design allows water to flow through easily, reducing the risk of slipping or water accumulation, making it ideal for factories, docks, or areas with strong water flow.

- Easy to Install and Maintain: It uses quick-assembly components that are easy to remove when replacement or routine maintenance is required.

-

Common Applications of Composite Grating Flooring

With its outstanding features, composite grating flooring is widely used in industries such as:

- Manufacturing plants, food processing factories

- Chemical storage areas, oil & gas, petrochemical facilities

- Ports, docks, airports

- Public projects requiring high anti-slip and corrosion resistance standards

In this section, we have a general overview of composite grating flooring. Next, let's compare it with other types of flooring based on important criteria such as durability, cost, environmental suitability, and ease of installation.

Comparing Composite Grating Flooring with Concrete Flooring

Concrete flooring is the most common type of flooring used in both residential and industrial construction. It can either be poured in place or precast into prefab panels. When compared to composite grating flooring, many technical and economic performance factors will be presented to help you make an informed decision.

Characteristics of Concrete Flooring

Concrete flooring is capable of bearing heavy loads, maintaining stability over long periods, and is suitable for projects requiring heavy loads or fixed foundations. This flooring system is also quite diverse in design, thickness, and installation methods.

However, concrete flooring has significant drawbacks regarding weight, long installation times, and difficulty in replacement or repair when issues arise. Especially in chemical environments, concrete is prone to corrosion and damage.

Comparison of Durability and Load-Bearing Capacity

| Criteria | Concrete Flooring | Composite Grating Flooring |

|---|---|---|

| Durability | High, suitable for the heaviest loads | Moderate, suitable for medium loads and below |

| Load-Bearing Capacity | Very good, can withstand large compression forces | Good, but more limited than concrete |

| Corrosion Resistance | Poor unless treated properly | Excellent, optimal corrosion resistance |

While concrete flooring shows advantages in durability and load-bearing capacity, composite grating flooring stands out with its corrosion resistance, lightweight, and ease of installation and maintenance.

Cost and Installation Time

The initial cost of concrete flooring is usually higher due to the need for pouring, drying, and various methods for waterproofing and crack prevention. The installation time is longer, especially in large projects or when renovation and upgrades are required.

In contrast, composite grating flooring can be installed more quickly, reducing waiting time and labor costs. The simple assembly system helps save a significant portion of the project budget.

Which Environment is More Suitable?

In heavy industrial environments, with many chemicals or water exposure, composite grating flooring shows a distinct advantage due to its corrosion resistance and ease of cleaning. Concrete flooring, on the other hand, is highly susceptible to quick damage in these environments if not properly protected.

Conclusion of Comparison

Concrete flooring is suitable for fixed constructions requiring heavy loads and long-term use. On the other hand, composite grating flooring is ideal for areas requiring quick water drainage, lightweight, easy maintenance, and resistance to harsh conditions.

Comparing Composite Grating Flooring with Steel Flooring

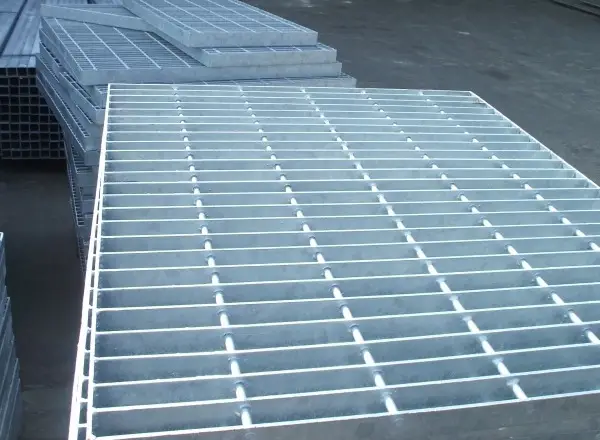

Steel flooring has long been a popular choice in industrial construction, particularly for stair systems and work platforms. So, when compared to composite grating flooring, which is the best option for each specific use?

Characteristics of Steel Flooring

Steel flooring is typically made from alloy steel or stainless steel, with high rigidity and superior load-bearing capacity. Most steel flooring systems are resistant to heat and impacts.

However, steel is prone to rusting if not treated with protective coatings or paint, especially in humid environments, sea salt, or corrosive chemicals.

Comparison of Corrosion Resistance and Lifespan

| Criteria | Steel Flooring | Composite Grating Flooring |

|---|---|---|

| Corrosion Resistance | Depends on coating, can rust if untreated | Excellent, naturally corrosion-resistant, minimal maintenance |

| Lifespan | High if well protected | High, especially in harsh environments |

| Repairability | Easy to repair, replace small parts | Easy to disassemble, quick repair |

Steel is a tough material, ideal for projects requiring high load-bearing capacity and heat resistance, whereas composite grating flooring excels in corrosion resistance, suitable for harsh climates, and is easier to maintain.

Cost, Installation, and Maintenance

The initial cost of steel flooring is typically higher due to surface treatment, coating, and manufacturing technology. The installation process also requires more specialized skills and takes more time.

Composite grating flooring has the advantage of quick installation, reducing time and maintenance costs in the long run, and is more environmentally friendly since there’s no need for continuous rust-proof coating.

Suitable Applications

For projects that require high load-bearing capacity, steel is the optimal choice. However, if the project prioritizes corrosion resistance, easy installation, and lower cost, composite grating flooring is the smarter choice.

Comparing Composite Grating Flooring with Wood Flooring

In interior design, decoration, or restaurants, wooden flooring has always held a special place due to its natural beauty and warm feel. However, technically, when compared to composite grating flooring, what stands out?

Characteristics of Wood Flooring

Wood flooring can be either natural or engineered, ranging from hardwood to engineered wood. It offers high aesthetics, a comfortable feel underfoot, and creates a cozy, luxurious environment.

However, wood flooring is highly susceptible to moisture, termites, warping, and is limited in high humidity or water-exposed environments.

Comparison of Durability and Load-Bearing Capacity

| Criteria | Wood Flooring | Composite Grating Flooring |

|---|---|---|

| Durability | Moderate, prone to damage over time | Excellent, resistant to termites, mold |

| Load-Bearing Capacity | Moderate, depends on wood type and structure | Good, suitable for industrial environments |

| Maintenance | Frequent cleaning and termite treatment | Low maintenance, easy to clean |

While wood flooring is ideal for interior spaces requiring natural beauty, composite grating flooring is more suitable for industrial areas, outdoor environments, or places requiring higher load-bearing and corrosion resistance.

Cost and Installation

Wood flooring installation can be more expensive due to fabrication, termite treatment, and regular maintenance. On the other hand, composite grating flooring can be installed quickly, saving time, labor costs, and is easier to maintain.

Choosing the Right Option

The choice between wood flooring and composite grating flooring depends on the intended use, aesthetic requirements, and load-bearing capacity. For projects requiring high aesthetics, wood flooring is the ideal choice. Conversely, for industrial or outdoor projects, composite grating flooring is the better option.

Conclusion

Comparing composite grating flooring with other flooring types like concrete, steel, or wood clearly shows that each has its own advantages and limitations based on the intended use. In environments requiring corrosion resistance, lightweight, easy installation, and low maintenance, composite grating flooring stands out as an optimal solution, providing exceptional economic and technical benefits. This technology is continuously evolving and expanding its applications across various fields, contributing to the enhancement of project quality and ensuring maximum safety for users.

Conclusion

On the journey of comparing composite grating flooring with traditional flooring types, we can clearly see that this type of flooring is the perfect combination of technical features, durability, and aesthetics, meeting the increasingly high requirements of modern construction projects. Choosing the right flooring not only helps optimize costs and installation time but also ensures safety and long-term effectiveness for your project.